Air-curable Conductive Copper Pastes

Key Features

Heat curing conductive material with copper filler

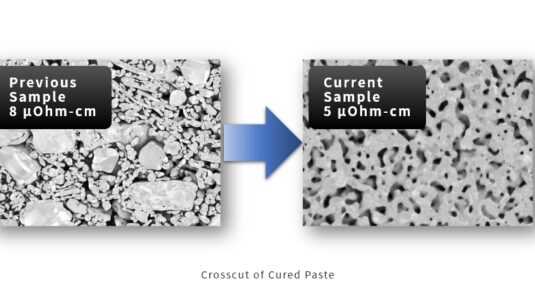

Excellent conductivity at air-curing

Better performance than materials with silver filler in;

- Migration resistance

- Stability of material cost

Lineup

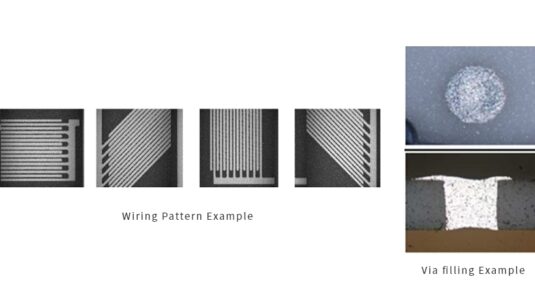

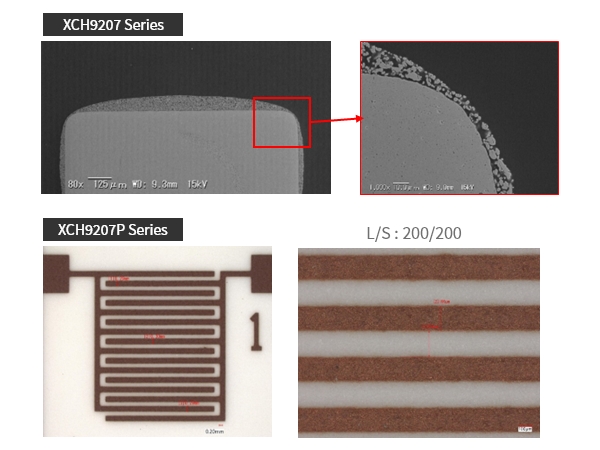

- XCH9207 Series

Low viscosity and low thixotropy paste

Suitable for various applications, especially dipping - XCH9207P Series

High viscosity and high thixotropic paste

Suitable for various applications, especially screen-printing

Property Data

| Copper Filler Diameter [μm] | Curing Conditions | Viscosity [Pa·s] | Specific Resistance Value[Ω·cm] | |

|---|---|---|---|---|

| XCH9207 | 5 | 200 ℃, 30 min. | 40 | 3×10-5 |

| XCH9207P | 5 | 200 ℃, 30 min. | 200 | 6×10-5 |

Related Products

CONTACT

For inquiries or consultation regarding our products, please contact us on the following page.