Small but Global

To the world with technology that is Only one, Number one!

Toshinobu Odajima,

President

Focus on deepening essence, rather than on the scale

I do not want to turn NAMICS into a large corporation.

What I am aiming for is not the scale, but essence. Developing technologies that only NAMICS can possess, leading at the cutting edge of electronics as a global company -- that is our management policy, " Small but Global."

Products that can contribute at the cutting edge of electronics

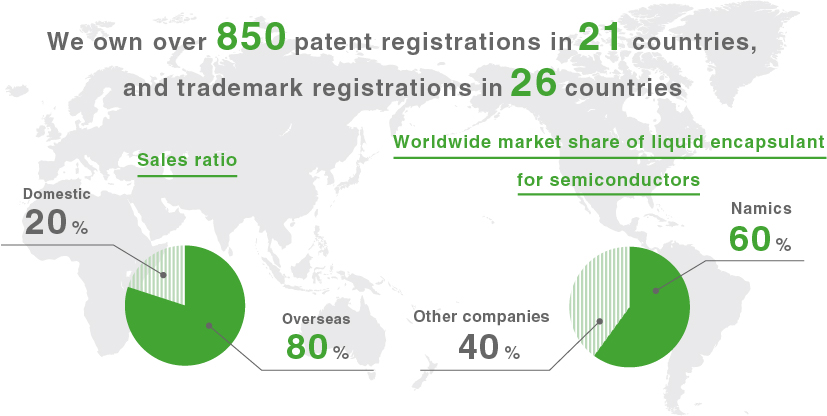

Since the foundation, we have evolved and specialized in electrochemical materials and developed and manufactured insulating and conductive materials. We develop various products responding to the level of sophistication of the customer's requirements. The number of fields where NAMICS has gained the top share in the world is not small, though the fields may be of a small scale. Currently, we own over 380 patent registrations in 10 countries, and trademark registrations in 26 countries. As a result, 80% of our sales are from overseas, and for liquid encapsulant for semiconductors, we account for 40% of the world market share.

The fact that products developed by us can contribute to the cutting edge of the electronics field worldwide, gives me pleasure and motivation to run the company. To realize this, we have maintained the ratio of engineers among all employees at 30% for 50 years and focused on technological development. Many of them are engineers who specialize in chemistry but combined with engineers with knowledge in fields such as pharmacy, electronics, physics, etc. we have created a system that can respond quickly to a wide range of customer needs.

Human resources pursuing the ideal with flexible thinking

NAMICS is an R&D-oriented company, requiring a logical way of thinking. But that is not all. A global perspective and flexible thinking are also critical. Because we create things that are not in already there in the world, it is necessary not to be stuck too much with technical possibilities, the efficiency of production or cost-effectiveness. Instead, expressing ideals and talking about dreams -- so to speak, being able to freely ideate as in liberal arts are also required.

That is why we emphasize "sensitivity." Even if one knows something, that knowledge cannot be utilized unless one can notice. Sensitivity is also necessary to understand how to perceive an event, how to recognize the problem, and how to sense the emotions of others. And this also leads to communication skills and is the backbone of human resource education.

In addition, together with the expansion of overseas deployment, human resources possessing knowledge of foreign languages, cultures, and values, knowledge of intellectual property rights management including the acquisition of patents/trademark rights, and human resources involved with their education are also required. We believe that a wide range of knowledge and experience, flexible thinking and challenging spirit will shape the next generation of NAMICS.

We challenge ourselves to 300 development projects per year

Products created by us will support the performance of electronic equipment. Therefore, we must evolve with the development of electronic equipment. With the spread of IoT and AI, electrical and electronic products and the services using them have shown unprecedented progress by increasing their variations at a speed that has not been so far. Among them, what we are paying attention to now is the sensor function. Their core has semiconductors, and NAMICS' products are used there.

Self-driving, detection of heat, vibration, and light, as well as imaging systems constitute the core of various industries including transportation, healthcare, crime prevention, disaster prevention, etc. It is not easy to read how far it will spread and what will be required at that time. In addition to consumer preferences, events, such as institutions, laws, and the natural environment, combine to create a significant trend. Therefore, the prediction is difficult. We must keep proceeding with a broader view without predetermining the future.

Those at the start of new technology are always a minority, but such a finely detailed niche field is what NAMICS is good at. In the development department, we are working on about 300 themes in a year, including large and small ones. Some of these are a continuation of a long-term study aiming for the next generation, but for about 30 to 40% of the projects, we have accomplished their commercialization.

For example, regarding materials, following the liquid encapsulant, conductive paste, film adhesive, we are developing materials for electromagnetic shielding. Currently, with communication equipment, sensors and so on have increased drastically, the electromagnetic noise of various frequency bands is flying around us. It is a material that has the shielding effect against noise that is necessary under such circumstances. It is a new technology to cope with weight reduction, cost reduction and miniaturization of modules.

Invest in the future to open the possibilities

Since NAMICS is a company that produces things that are not already there now, to match this, we have created the NAMICS Techno Core in a freshly designed building, not in a pre-existing structure. We wanted a design that makes one think what it means to create a new thing. It has a significant impact on business visitors and observers, and for employees, it has been a motivation for developing new products.

Subsequently, we have started a project to restructure the headquarters, aiming for completion in 2022. By promoting the consolidation/enhancement of headquarters functions and factory, we will pursue the improvement of operational efficiency from the connectedness of the employees and a new form of working style.

It is an investment with the breakthrough into the future and advancing manufacturing flexibly in mind. Total construction cost will be 20 billion yen, and the production capacity will be over 170% of current once it is complete. From here is the prelude to the future. A new story starts again from here.