Development of a nano anchoring treatment technology for a copper foil surface to provide low roughness, high adhesion, and high reliability and the copper foil prepared by the technology

12/16/2019

Motivation

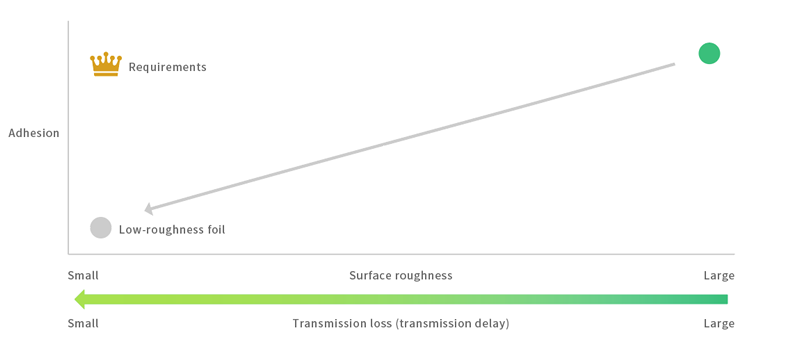

- Smart technologies such as IoT (Internet of Things), 5G, and autonomous driving require high-speed and high-volume data processing. Thus, high-frequency applicable substrates are used.

- High-frequency substrates mainly use copper wiring. Copper wiring without low surface roughness delays high-speed transmission.

- On the other hand, if the copper wiring’s surface is too fine, it does not provide sufficient anchoring effects, decreasing the adhesion. We need to balance the trade-off between the transmission performance and adhesion associated with the copper surface roughness.

Issue

The copper wiring on high-frequency substrates is required to have a surface that satisfies (1) low roughness, (2) high adhesion, and (3) surface stabilization (prevention of performance degradation).

Results and Findings

- Low roughness, high adhesion, and surface stabilization have been achieved by varying surface treatment agents

Background of the issue

Motivation for the development

- Smart technologies such as IoT (Internet of Things), 5G, and autonomous driving require high-speed and high-volume data processing. Thus, high-frequency applicable substrates are used.

- High-frequency substrates mainly use copper wiring. Copper wiring without low surface roughness delays high-speed transmission.

- On the other hand, if the copper wiring’s surface is too fine, it does not provide sufficient anchoring effects, decreasing the adhesion. We need to balance the trade-off between the transmission performance and adhesion associated with the copper surface roughness.

Therefore, in order to overcome this trade-off, we started developing copper surface treatment technology that can provide both low roughness and high adhesion.

Overview of the development

Our development steps were as follows:

-

Step 1

Investigation of surface treatment agents that provide low roughness and high adhesion

-

Step 2

Investigation of surface treatment agents that stabilize the surface

Concept of the development

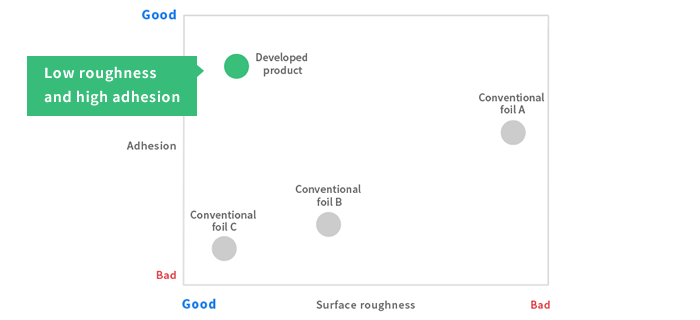

Step 1. Investigation of surface treatment agents that provide low roughness and high adhesion

Our approach was based on the hypothesis that the adhesion can be increased even on low roughness surfaces by increasing the surface area. Conventional surface treatment agents tend to rapidly form whisker-like unevenness in a short time, which leads to non-uniform roughness with a large deviation.

In order to solve this problem, controlling the formation speed of the whisker-like unevenness with an additive was thought to be effective.

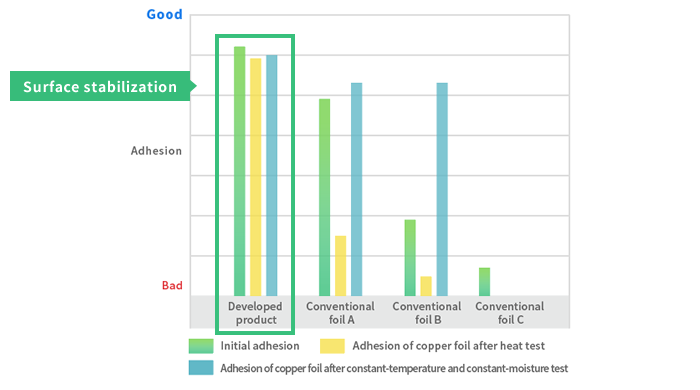

Step 2. Investigation of surface treatment agents that stabilize the surface

In order to ensure high reliability, we also decided to add a surface stabilizing group to the whisker-like unevenness obtained in Step 1.

Results and Findings

Step 1. Select the additive and optimize its concentration

A surface treatment technology that provides both low roughness and adhesion was successfully developed.

Step 2. Add a surface stabilizing group

A good copper surface was obtained that has all three features: low roughness, high adhesion, and high reliability.

| Exhibition | Mate 2019 |

|---|---|

| Presentation title | Development of a nano anchoring treatment technology for a copper foil surface to provide low roughness, high adhesion, and high reliability and the copper foil prepared by the technology |