Development of a spray-coated paste for electromagnetic wave shielding

01/15/2019

Motivation

- Recently, electromagnetic noise has increased as the number of telecommunication devices increases, leading to a serious issue of malfunction.

- Conventionally, noise is shielded using a metal plate; however, the metal plate has issues to be overcome, including the weight, thickness and difficulty in processing.

- We started the development with the assumption that the current issues can be solved if we can shield any object regardless of the size and shape flexibly.

Issue

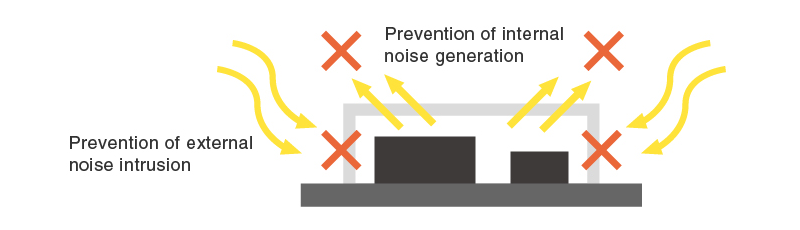

- In the environment where electromagnetic wave noise in a wide range of frequencies exists, both the internal and external noise the highly integrated semiconductor components are exposed to must be shielded component by component.

Results and Findings

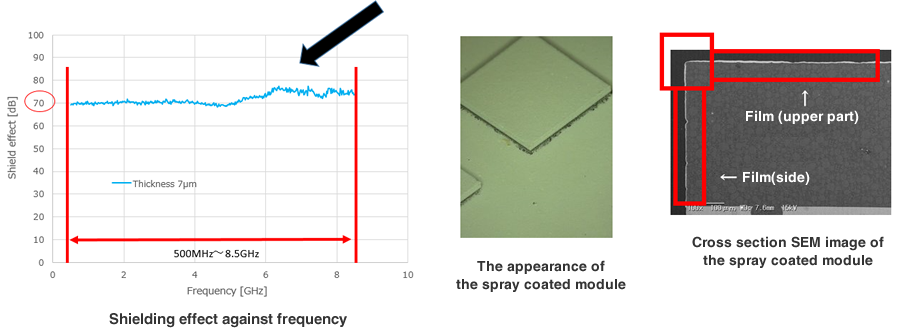

- We have succeeded in developing a spray applicable conductive paste.

- Our newly developed paste provides a film with 5 to 6 µm upper thickness and 3 to 4 µm side thickness to our target of 10 µm or less film thickness.

Background of the issue

Motivation for the development

- The spread of the Internet has rapidly increased the number of telecommunications devices and sensors, allowing electromagnetic wave noise in a wide range of frequencies to be present in our surroundings.

- The internal and external noise the highly integrated semiconductor components are exposed to must be shielded component by component.

- Conventionally, the module was coated with metal, but as the trend is moving toward lighter, cheaper, and smaller modules, we saw an opportunity to develop a new conductive paste using NAMICS’ specialty technology to replace the metal material.

Overview of the development

2010 Research of printed-type paste

| Process | Cost | Film thickness | |

|---|---|---|---|

| Screen printing | Dry✓ | High× | thick× |

| Alternative technology (electroplating) | Wet× | low✓ | thin✓ |

| Sputtering (metal vapor deposition) | Dry✓ | High× | thin✓ |

We selected sputtering method despite its high cost because it enables thin coating in a dry process.

- For shielding using sputtering, stainless steel, copper, and stainless steel are deposited to make a three layers.

Higher conductivity provides more secure shielding; however, this requires thicker film and extended process time. - In order to respond to increasing high frequencies, higher shielding property is required; however, sputtering needs longer process time for a thicker film.

Sputtering cannot satisfy our needs, so we shifted our development concept to a thinly applicable paste.

Concept of the development

- A thinly applicable conductive paste for shielding

At first, we investigated printed-type paste with a solventless conductive paste selected for being nonvolatile.

However, the solventless system, since there is no volatile component, leads to the thick coated film.

For thin coating, we selected a solvent system with a low viscosity (existing technology for NAMICS) with a thin coating process (spray technique which was acquired). - Sprayable (low viscosity), high shielding property (high conductivity)

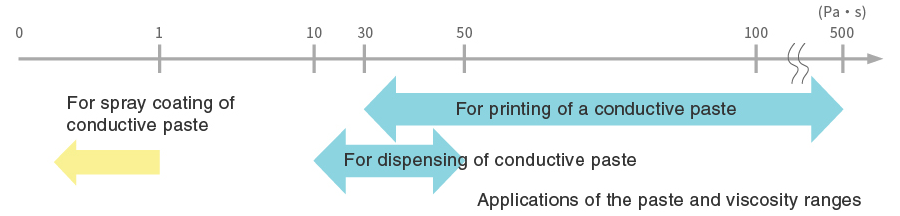

We aimed for low viscosity which is a trade-off with high conductivity, a core technology of NAMICS that we took advantage of. - Viscosity

For printing of conductive paste 500 to 30 Pa·s a core technology of NAMICS For dispensing of conductive paste 50 to 10 Pa·s a core technology of NAMICS

Acquisition of new technology

For spray coating of conductive paste less than 1 Pa·s

Results and Findings

- Through selecting a low viscosity resin, a filler which can lower viscosity and resistance, the shape of the filler, and a solvent, we have successfully developed a sprayable conductive paste.

- Our newly developed paste provided a film with 5 to 6 µm upper thickness and 3 to 4 µm side thickness to our target of 10 µm or less film thickness.

| Exhibition | ICEP 2018 |

|---|---|

| Presentation title | Sprayable silver paste with good shielding characteristics in high frequency band |