Establishment of resin design method by simulation:

On the fluidity of resins

03/23/2020

Motivation

- Resin materials are treated as fluids in various environmental conditions such as high temperature or high shear, but their behavior is difficult to predict.

- It is necessary to clarify their mechanism as a fluid so that their behavior can be predicted.

- Therefore, we started to develop a method for predicting their behavior using simulation.

Issue

To clarify the mechanism of resin using simulation and to develop the optimal product satisfying the customer requirements in a short time.

Results and Findings

- A simulation method that can analyze the behavior of resin as a fluid was developed

- At present, we are responding to the needs of engineers and customers by analyzing which resin is the best.

Background of the issue

Motivation for the development

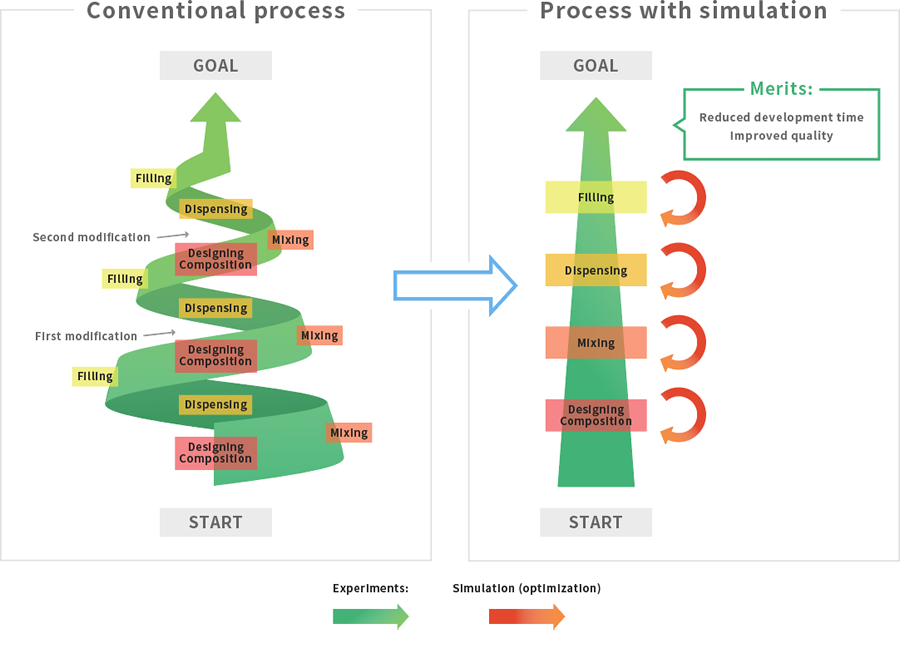

In our company, thermosetting resin and conductive resin are used in various electronic parts starting from the fluid state, but the determination of their success or failure had to be made by repeating actual experiments and observing the results.

The process required a lot of man-hours and materials, yet still did not promise the optimal quality of a product.

Therefore, in order to clarify the behavior of resin as a fluid and to provide the optimum product satisfying the customer requirements in a short time, we started to study the product design method using simulation.

Development concept (Introduction of the simulation and analysis technologies)

The important factors in our product development include the following.

- Conditions for uniformly mixing and dispersing additives in a resin

- Optimal conditions for dispensing our developed products

- Conditions under which our products can be filled faster and more uniformly into narrow gaps

The next section shows an example of analyzing the optimal conditions with regards to these three points using simulation technology.

Results and Findings

- The appropriate simulation software was selected while keeping in mind the concept of the development. Together with the software developer and the resin design engineer, the properties of the resin and the analysis method were optimized based on the actual resin behavior. As a result, a simulation method capable of analyzing the behavior of the resin as a fluid was developed.

- At present, we are responding to the needs of engineers and customers by analyzing which resin is the best.

Simulation and analysis examples:

Analysis example 1

Video of analysis of uniform mixing and dispersion conditions using simulation technology

Analysis example 2

Video of analysis of the optimal conditions for dispensing the developed products using simulation technology

Analysis example 3

Video of analysis of the product characteristics of being quickly and cleanly filled into gaps using simulation technology

| Exhibition | Prometech Simulation Conference 2017 |

|---|---|

| Presentation title | Study of resin flow analysis using Particleworks |