Development of Low-temperature Sinterable Ag Nano Paste

04/13/2022

Motivation

Wider IoT availability calls for more flexible applications. Materials for flexible application must be processed at low-temperature. Wiring materials in such applications require good electrical conductivity and flexibility in a thin film form.

Issue

Ensures low-resistance wiring in low-temperature processes to support organic substrates with low heat resistance

Results and Findings

- Successful development of Ag paste which provides specific resistance of 7.1 x 10-6 Ω·cm by sintering at 120℃/30 minute drying

- For wiring with this paste, screen-printing is supported.

Background of the Issue

Motivation for the Development

- Wider IoT availability calls for more flexible applications.

- Materials for flexible application must be processed at low-temperature, which requires wiring materials to provide good electrical properties and flexibility in a thin film form.

- In the automotive sector, there will be increasing demand for more advanced cameras and sensors for autonomous driving, as well as demand for snow melting and anti-fogging solutions to support the increase in the number of cameras and sensors installed in automobiles. This indicates a potential demand for heaters.

Overview of the Development

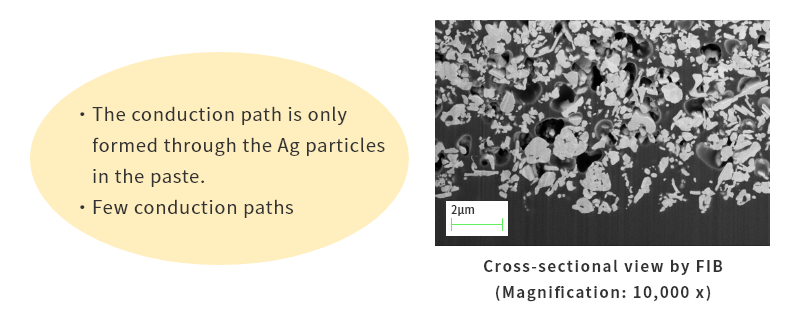

Conventional Ag paste for wiring/electrode formation can be sintered at 120℃/30 minute drying; however, the conductivity is provided only through Ag particles in the paste, which limits specific resistance to up to 2.5 x 10-5 Ω·cm.

Concept of the Development

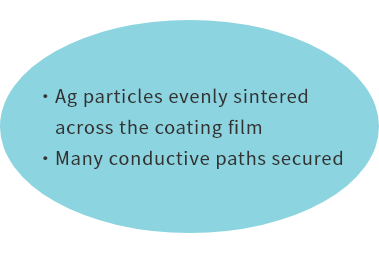

- Targets low resistance by sintering Ag filler at 120℃/30 minute drying.

- Ensures flexibility on a thin film with uniform sintering.

- Ensures adhesion to film substrates made of materials such as PC, PET, or PI by adding resin components.

Developed Technology

Sintering Ag filler at 120℃/30 minute drying

Results and Findings

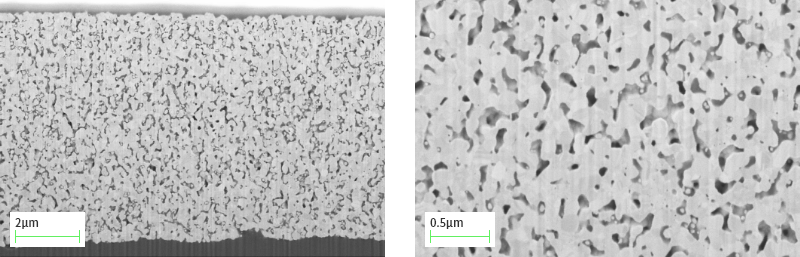

- Good sintering of Ag filler at 120℃/30 minute drying

- Specific resistance of 7.1 x 10-6 Ω·cm achieved

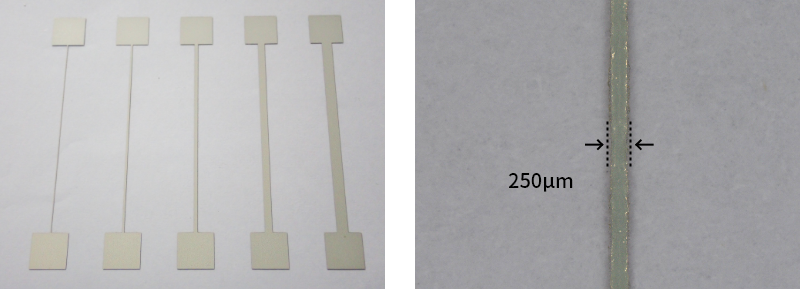

- Screen printing supported for micro wiring with 6 μm film thickness and 250 μm width

- Good adhesion and bending resistivity to film substrates made of materials such as PC, PET, or PI

- No deterioration of resistance after long-term reliability test

Ag wiring screen printed at 120℃/30 minute drying

Ag wiring screen printed at 120℃/30 minute drying

Cross-sectional view by FIB (Magnification: 10,000 x / 25,000 x)

Cross-sectional view by FIB (Magnification: 10,000 x / 25,000 x)

Prospective Applications

- Low-resistance wiring

- Printable heating wires

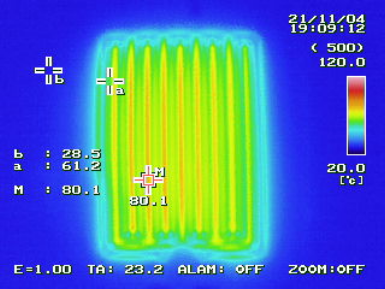

Heat generation image of printable heater using Ag electrodes

Heat generation image of printable heater using Ag electrodes