Leveraging Our Cultivated Production Technologies

NAMICS Smart Agriculture

Building Sustainable Agricultural Models with Data and Technology

At NAMICS, by applying technologies cultivated through manufacturing, we are making progress on new challenges that contribute to the region and the future.

At the Lab. in Kita Ward of Niigata City where we conduct smart agriculture demonstrations, we are working to create new cultivation models based on data.

Why is a Materials Maker in Agriculture?

NAMICS decided to step into the world of agriculture because we believed that as a manufacturing company there are ways we could contribute to solving problems faced by the regional agricultural industry. In Niigata, many issues threaten the continuation of agriculture including an aging population, lack of workers, and climate change. That is where our company began to explore sustainable forms of agriculture by leveraging precise environmental control, quality management, and data analysis technologies we have cultivated in our manufacturing facilities.

While this began as part of our CSR activities, it has now advanced to a stage focused on business expansion. “Mastery of Agriculture through data, not experience or intuition.” At NAMICS, our goal is to make it so anyone can grow crops stably through our data-and-science-based approach.

Currently, we are conducting repeated demonstrations and verifications of smart agriculture at our Lab. based in Kita Ward, Niigata City. By leveraging our expertise in manufacturing, we aim to enhance reproducibility in agriculture. This endeavor also represents an attempt to nurture the seeds of new industries that will support the region's future.

Implementing Smart Agriculture Using a Former Elementary School Site

The Lab. in Kita Ward, Niigata City serves as the base for NAMICS’s agricultural operations and smart agriculture demonstration projects. Spanning approximately 6,600 square meters on the site of a former elementary school, the demonstration facility features three greenhouse structures and three fully enclosed plant production rooms.

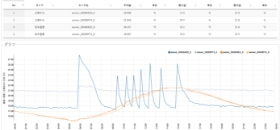

Here, the environment is automatically controlled based on the data collected by sensors measuring temperature, humidity, solar radiation, CO₂ concentration, and other factors. Inside the greenhouse, shading curtains, ventilation systems, and irrigation system are coordinated to maintain optimal conditions for the crops. This enables stable production that is minimally affected by weather and seasonal changes. The collected data is stored in the cloud, enabling centralized analysis of information such as photosynthesis, transpiration, and nutrient solution balance. These results are applied to subsequent crops, making for agriculture that continuously improves.

The role of Kita Ward's farm is to develop cultivation techniques. Through the verification and research conducted here, we aim to realize sustainable agricultural businesses while encouraging those who wish to pursue farming, fostering a regionally sustainable agriculture that cultivates new practitioners.

Data-Driven Optimization of Cultivation Environments

We are currently tackling the challenge of optimizing tomato cultivation based on data. Environmental factors such as temperature, humidity, sunlight intensity, and CO₂ concentration are constantly monitored by sensors, with the data analyzed in real time. Based on the results, ventilation, irrigation, and the operation of shade curtains are automatically controlled to maintain the environment most conducive to crop growth.

Additionally, we apply statistical quality control principles honed in NAMICS manufacturing facilities, in order to cross-reference environmental data with growth data. We interpret photosynthesis, transpiration, and nutrient solution composition as “numerical relationships,” in pursuit of conditions that enhance sweetness and yield. This enables scientific tomato cultivation that does not rely on experience or intuition. One such outcome is high-sugar tomatoes exceeding 10 degrees Brix. While typical tomatoes have a sugar content of around 4 to 6 degrees Brix, NAMICS' hydroponic tomatoes average 9 to 11 degrees Brix, with a maximum recorded at 12 degrees Brix. The harvest period spans approximately 9 months, and it has been proven that stable quality can be maintained over this long period.

This Lab. also serves as a location for NAMICS’ experimental facility, using data to unravel the question of “how can we reproduce delicious results?” through research and demonstration in smart agriculture. The outcomes generated here will lead to new cultivation models and educational programs in the future.

The Journey to Growing Tomatoes with a Sugar Content of 10 Degrees or Higher

At our Lab. in Kita Ward, Niigata City, we achieve long-term cultivation of high-sugar tomatoes using “film cultivation” which grows plants without soil, using special film and nutrient solution. The cultivation process, spanning approximately 11 months, is as follows:

-

Transplanting (2 weeks)

Selected seedlings are planted in cultivation beds where the sunlight, temperature, humidity, and irrigation conditions are controlled. This helps to stabilize initial root growth and plant establishment.

-

Environmental Control (Continued from Month 1)

Sensors continuously monitor temperature, humidity, sunlight intensity, and CO₂ concentration. Factors such as shading curtains and ventilation are automatically controlled to maintain the optimal environment for promoting photosynthesis.

-

Nutrient Solution Management (Continued from Month 1)

We analyze and adjust the composition and volume of nutrient solution supplied to roots on a weekly basis. By precisely controlling moisture and nutrients, we induce the right amount of stress to enhance sweetness.

-

Flowering and Pollination Management (Continued from Month 1)

During the flowering period, pollination is performed using bees. Optimal environmental control and nutrient solution management stabilize flowering and fruit growth.

-

Harvesting (Continued from Month 3)

Harvesting is possible for approximately 9 months, longer than typical tomato cultivation. The sugar content significantly exceeds that of standard tomatoes (4–6 degrees Brix), yielding high-sugar tomatoes with 9–12 degrees Brix.

NAMICS’ Vision of The Future of Agriculture

In addition to our Lab. in Kita Ward, Niigata City, we are making progress on our next planned agricultural hub in Nishikan Ward which is positioned as a center for disseminating the achievements of demonstration-based smart agriculture to society at large. We aim to create a space where many visitors can become familiar with smart agriculture through experiences of “seeing, touching, tasting, and learning,” thereby contributing to the region's food culture and the development of the next-generation’s talent.

On the other hand, NAMICS’ cultivation technology development is still in its early stages, with only the collection of foundational data and partial improvements having begun. As regional agriculture faces various challenges, including welcoming novice farmers, abnormal weather, and business profitability, we aim to collaborate with diverse partners both domestically and internationally to address these issues.

Through sustainable, locally-circulating agricultural models, the future of farming will become more accessible and open to all.

From Niigata, NAMICS will continue our journey toward realizing this vision of “farming accessible to everyone.”