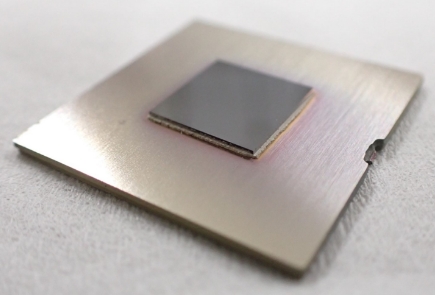

Low-temperature-sintering High thermal-conductivity Die Attach Adhesives Using MO Technology (conductive, sintering type)

Key Features

Low-temperature sintered high thermally conductive die attach pastes using MO technology

Materials with higher heat-dissipation are required as device development seeks higher density and integration.

Low-temperature curable highly thermally conductive die attach materials has been developed using MO technology. Products are available including one that provides thermal conductivity of more than 200 W/mK.

Samples are available upon your request.

Property Data

| Product Number |

Characteristics | Applications | Viscosity [Pa・s] |

Curing Conditions |

Volume Resistivity [Ω・cm] |

Adhesive Strength [N/mm2] |

Thermal Conductivity [W/mK] |

|---|---|---|---|---|---|---|---|

| H9892-5 | Silver sintering material for pressure bonding Bond to bare copper substrate Good for temporary bonding of elements with heat Good for printing application |

Power IC SiC、GaN |

40 (E type 5rpm) | Pressure: 15MPa Temperature: 300Co Time: 2min. |

2.7×10-6 | 80 | 250 |

| H9888-2 | Silver sintering material for pressure-less bonding High density and very high thermal conductivity type Good for dispensing application |

Power IC SiC、GaN |

35 (E type 5rpm) | RT -> 210C for 62min, hold for 60min |

5×10-6 | 85 | 275 |

| H 9890-6A | Silver sintering material for pressure-less bonding High thermal conductivity type Good for dispensing application |

Power IC SiC、GaN |

30 (E type 5rpm) | RT -> 200C for 60min, hold for 60min |

8×10-6 | 50 | 140 |

| H 9890-10A | Silver sintering material for pressure-less bonding High thermal conductivity type with low bleed-out property Good for dispensing application |

Power IC SiC、GaN |

30 (E type 5rpm) | RT -> 200C for 60min, hold for 60min |

8×10-6 | 75 | 140 |

| H 9890-11 | Silver sintering material for pressure-less bonding Thermally conductive and low modulus type Good for dispensing application |

Power IC SiC、GaN |

30 (E type 5rpm) | RT -> 200C for 60min, hold for 60min |

15×10-6 | 35 | 60 |

Related Products

CONTACT

For inquiries or consultation regarding our products, please contact us on the following page.